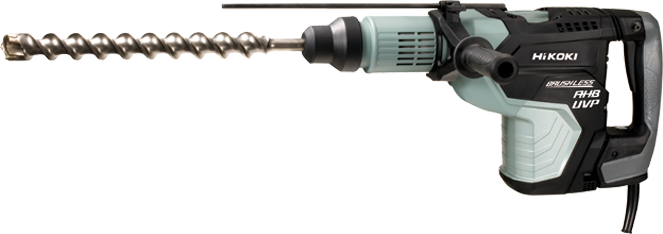

AC Brushless Motor Technology by HiKOKI

A HiKOKI technical advancement. After pioneering the use of brushless motors in cordless tools, now we’ve applied their benefits to electric corded tools with astonishing results.

Get your hands on a compact and lightweight range of tools with really heavy-duty power. By reducing the number of moving parts in the motor we’ve decreased tool size and weight but increased power output.

HiKOKI brushless AC motors deliver greater durability and longer life even under heavy use. There are no carbon brushes to regularly replace and no risk of armature burnout, layer short or commutator wear.

While the electronic circuit board is silicone-coated to protect from dust.

Because brushless motors run cooler, look forward to stable performance even when there’s voltage drop from using long extension cords. Equipped with a highly efficient inverter circuit, HiKOKI AC brushless motors are compatible with engine generators that don’t have an onboard inverter.

Lighter. Easier to use.

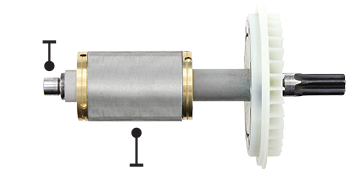

The HiKOKI AC brushless motor is more compact and lightweight than conventional motors. For instance, if you compare the motors of the WR16SE Brushless Impact Wrench with the WR16SA Brushed Impact Wrench.

The brushless motor offers a significantly extended product life cycle by eliminating trouble including armature burnout, layer short or commutator wear.

Resistant to Voltage Drop. The HiKOKI AC brushless motor is scarcely affected by the applied voltage, offering steady performance even when using an extension cord or generator.

Maintaining speed under load ensures stable performance and high efficiency.

A rear fan efficiently cools the motor for more durability.

Safety Conscious

Brake system: The motor stops shortly after the tool is turned off, so users can put the tool down quickly and move onto other projects.

0-Voltage Restart Protection: The motor does not restart after the power has been temporarily cut off during operation to avoid accidents.

Kickback Protection: When a sudden drop in motor rotation speed is detected, the motor rapidly stops to reduce the kickback.

Soft Start: Start-up torque is reduced for better control.